Mastering the Art of Silk Screen Printing on Shirts

Screen printing, also known as silk screening, is a versatile and widely-used printing technique for creating vibrant and durable designs on shirts and other textiles. With its rich history and enduring popularity, screen printing remains a favorite among artists, designers, and apparel manufacturers alike. As we provide Screen printing in Dallas and if you search for t shirt screen printing near me then you will find us on top. In this article you will learn more about this printing method.

Understanding Screen Printing on Shirts:

Screen printing is a method of printing where ink is transferred onto a substrate (such as fabric) through a mesh screen stencil. Each color in the design requires a separate screen, allowing for precise color placement and vibrant prints. Screen printing is known for its durability, versatility, and ability to produce high-quality prints on a variety of materials. It’s commonly used for creating custom T-shirts, apparel, posters, and promotional items.

The Process of Screen Printing on Shirts:

Design Preparation:

-

- The screen printing process begins with the creation or selection of the design to be printed on the shirts. Designs can be hand-drawn, digitally created, or provided by the client.

- Once the design is finalized, it is separated into individual colors, and a separate screen is created for each color using a photosensitive emulsion coating.

Screen Preparation:

-

- Screens are made from a mesh material stretched tightly over a frame, typically made of aluminum or wood.

- The mesh is coated with a layer of photosensitive emulsion, which is exposed to UV light through a film positive of the design. The areas of the emulsion exposed to light harden, while the unexposed areas remain water-soluble.

Screen Printing Setup:

-

- Once the screens are prepared, they are aligned on the printing press in the correct sequence and position for printing.

- The shirts are placed on the printing platen, which holds them securely in place during printing.

Ink Mixing and Preparation:

-

- Ink is mixed and prepared according to the color specifications of the design. For precise color replication, many turn to Pantone color matching systems.

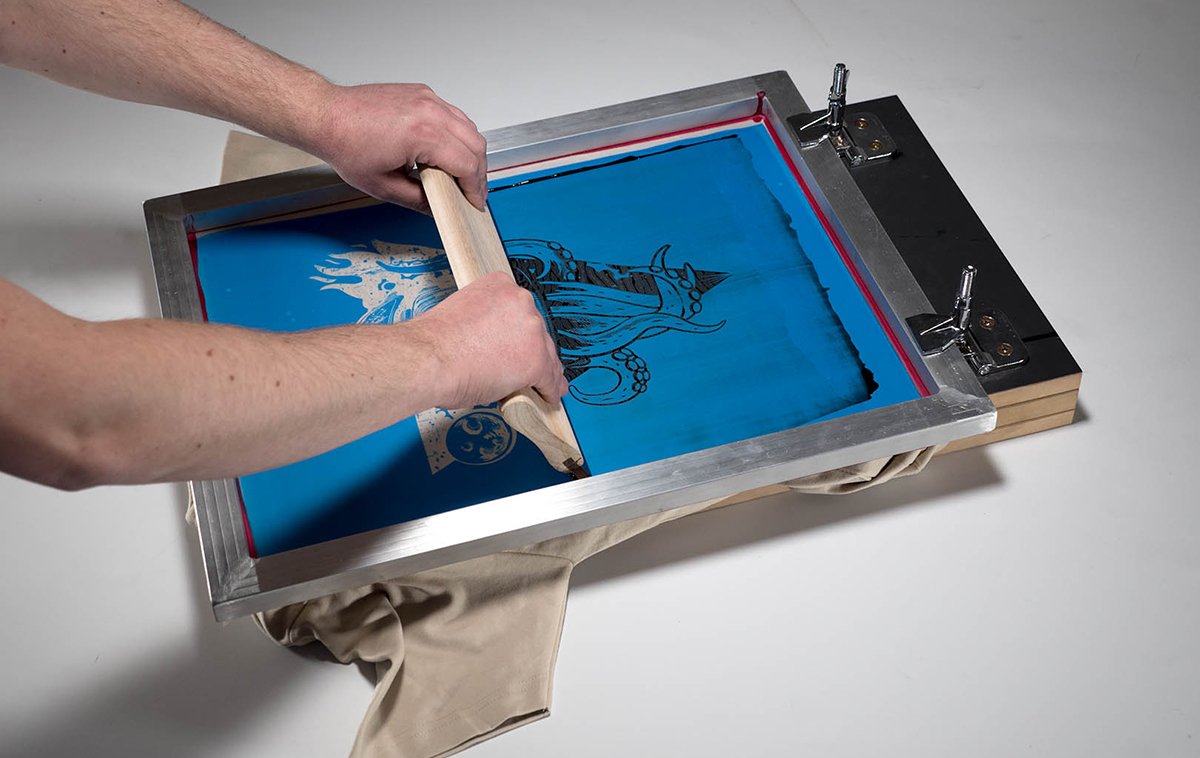

- The ink is poured onto the screen, and a squeegee is used to spread the ink evenly across the mesh, forcing it through the open areas of the stencil and onto the shirt below.

Printing Process:

-

- With the screens aligned and the ink prepared, the printing process begins. Each color in the design is printed separately, with the shirt passing under each screen in succession.

- The squeegee is pulled across the screen, transferring the ink onto the shirt as it moves along the printing platen.

- After each color is printed, the shirt is passed through a drying station to cure the ink and prevent smudging or bleeding.

Quality Control:

-

- Throughout the printing process, operators monitor the print quality and make adjustments as needed to ensure consistent results.

- After printing, each shirt undergoes thorough inspection to check for any defects, misprints, or inconsistencies.

Post-Processing:

-

- Once the ink is fully cured, the shirts may undergo post-processing steps such as heat pressing or steaming to set the ink and improve durability.

- Any excess ink or residue is removed from the shirts, and they are inspected one final time before packaging.

Packaging and Distribution:

-

- After post-processing, the shirts are folded, labeled, and packaged according to customer specifications.

- They are then ready for distribution or retail sale, either directly to customers or through wholesale channels.

Advantages of Screen Printing on Shirts:

- Vibrant Colors: Screen printing offers vibrant and opaque colors that stand out on the fabric, making it ideal for bold and eye-catching designs.

- Durability: Screen-printed designs are highly durable and long-lasting, able to withstand repeated washings and wear without fading or peeling.

- Versatility: Screen printing can be applied to a wide range of fabrics, including cotton, polyester, and blends, making it suitable for various types of apparel.

- Cost-Effectiveness: Although there are certain upfront expenses associated with screen printing, the process actually gets more economical as production runs increase, making it the go-to method for commercial printing jobs and big orders.

Conclusion:

Screen printing on shirts is an intricate and rewarding process that combines artistry, craftsmanship, and technology to create vibrant and durable prints. By understanding the steps involved and selecting the appropriate equipment and materials, printers can achieve professional results that meet the unique needs and preferences of their clients. Whether it’s for custom apparel, promotional merchandise, or retail products, screen printing offers endless possibilities for creativity and expression, making it a timeless and beloved printing technique in the world of textiles and apparel.